Instructions on how to unscrew a broken spark plug. Simple instruction how to unscrew a broken spark plug.

- Unscrewing instructions

- Possible difficulties in twisting

- Unscrewing instructions

- Carving on the NW and its restoration using futorki

The stuck spark plug can be unscrewed with “little blood” - without dismantling the head. Another option is to remove the head and drill a candle.

First of all try - to break the candle on a cold engine! (and only in the cold). With the help of an elongated head and a long crank.

Try to make the crank lever as long as possible - this will simplify the process.

Do not make sudden movements, because the candle may simply break - gradually increase the pressure on the shoulder.

Before unscrewing it is possible (and necessary) to process the candle with penetrating lubricant - WD-40.

In the absence of such, you can use - ordinary kerosene.

Also, it would not hurt to make several blows (slack) on the extension head or key - to tap !.

If the spark plug is not unscrewed through the wrong length of the threaded part (since part of it is in the combustion chamber is covered with carbon), then dismantling in the usual way becomes impossible!

It will only help the removal of the head.

When - "dead boiling" candles will not only have to remove the cylinder head, but also drill it.

You will get off with a slight fright if after drilling a thread remains in the head.

As a rule, a hole of larger diameter is drilled, an adapter sleeve is inserted into it, in which a new thread is cut under the candle.

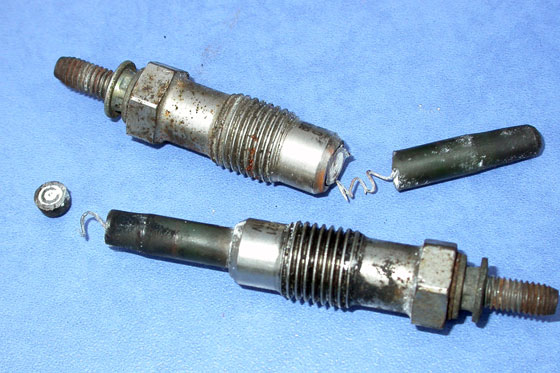

Broken candle? No problem!

Overtook me here the other day grief.

On a day off, it was decided to make an audit of my car. I drove into the garage and began to check all components and assemblies.

It came up to the spark plugs, took the candlestick, the instructor and the ratchet ( NEVER DOWNS THE CANDLES WITH A ROCKET ). And on the first candle that I wanted to unscrew, an emergency occurred.

The candle did not turn off, I had to make an effort, and since I took the tool with a ratchet and it looks like a 90-degree angle, with the application of force it turns out that the whole construction skews a little but not too much but that would be enough .

Crunch is heard, take out the head and see

Then there was a lot of PI PI PI ie I remembered my vocabulary of the great and mighty RUSSIAN language; I treated myself with various warm and tender words :) And I began to scratch a little turnful from shock, turnip - what to do.

I decided that here I could not help myself with anything and the only thing that occurred to me was to check if the engine could start and drag me to the service.

He threw three coils on the candles, put the key in the ignition lock, crossed himself and turned at the start. The engine immediately started up and after a successful launch, after half a second, there was a frightening strong cotton and then a blow, then I immediately turned off the ignition, the pulse increased, but I don’t go to the engine. I sit in the car, I'm afraid to go and remember a couple of dozen affectionate words addressed to me, well, I scratch all the tighter turnips that are already pretty bald. It took about thirty seconds and I still decided to make a truly manly brave act - the first steps to the engine.

To my pleasant surprise, it wasn’t as bad as I had imagined.

When the picture is enlarged, it can be seen that the central electrode is absent and the grounding electrode is seen in the depths.

After that, it became clear that the cotton and the blow was caused by the departing central electrode, spent 5 minutes searching for it, and soon there was such a picture in my eyes.

The rest remained in the head of the engine.

The first thing was the thought of hammering there with a hammer there would be no screwdriver and the like, and then try to unscrew, but common sense took hold of me, I closed the garage and went desperate home.

I started woolnetnet and it turned out that it was not me alone who got into such trouble and the network still had a chance to fix it.

In the shop specializing in tools taps are sold only with left-hand thread and a cone, they are called extractor. It was later, and I decided to postpone the search for this miracle thing. The next day, after confiscating the Civic in the morning, my wife left for work, drove into the store during the day and bought a set of these extractors

Since the extractor has a four-sided fastener part under the tap, and it is natural to not crawl so deeply, I picked up a head that was practically put on the extractor.

He came to the garage, missed the candle well with oil and began to prepare the tool.

Spark plugs are necessary for the formation of a spark in the combustion chamber, which ignites the fuel fluid. Starting of the engine, its uninterrupted operation, fuel consumption, etc. depend on them. Therefore, we must constantly monitor the cleanliness and integrity of the spark plugs. Candles must be cleaned of soot and soot. If the candle has broken, it must be replaced with a new one, since a car with such a malfunction cannot be operated. How to unscrew a broken spark plug, I will tell in this article.

The lifetime of igniters depends largely on the quality of gasoline and proper care for them. If the heating elements are cleaned regularly, this will increase their shelf life, since soot contributes to leakage. high voltage , which reduces the power of the spark or even prevents its appearance. True, if they overheat, uncontrolled drip ignition may occur. This is possible at high speeds, which causes detonation or may break down parts of a car engine. Usually after 30-40 thousand kilometers the candles need to be changed. When replacing it, you can accidentally break it, as it could stick to it. If such a nuisance has happened to you, then do not be afraid. By following the simple instructions for twisting a broken candle, you can easily handle it.

Before you begin to unscrew the igniters, you need to prepare. First, you need to wait until the engine has completely cooled. The aluminum cylinder head, when heated, expands and clamps the spark plugs in the thread, so it is impossible to unscrew them. In addition, the cold unit will protect you from burns.

For the unscrewing procedure it is necessary to prepare the following tools and materials:

- special hex;

- compressor;

- oil WD -40.

After the engine has cooled down, disconnect all the contacts. With the help of special tools and a clean cloth, it is necessary to thoroughly clean the location of the heating elements from dirt so that nothing falls into the candle well.  A compressor with a thin tube or another device forcing air must blow the well itself. This should be done very carefully, as there is usually a lot of garbage and dirt in the nest. After purging, add WD -40 oil to the socket. It will lubricate the threads and ease the unscrewing. It is possible to start work after 10-15 minutes after the oil has been poured.

A compressor with a thin tube or another device forcing air must blow the well itself. This should be done very carefully, as there is usually a lot of garbage and dirt in the nest. After purging, add WD -40 oil to the socket. It will lubricate the threads and ease the unscrewing. It is possible to start work after 10-15 minutes after the oil has been poured.

Unscrewing instructions

For unscrewing, you can use a special hexagon or torque wrench.  With the help of a torque wrench, the force is monitored during unscrewing, thereby preventing the thread from breaking. A simple key for unscrewing the igniter will not work, as it will not enter the well, besides, you can break the thread or break.

With the help of a torque wrench, the force is monitored during unscrewing, thereby preventing the thread from breaking. A simple key for unscrewing the igniter will not work, as it will not enter the well, besides, you can break the thread or break.

Each a heating element has a hexagon under the torque wrench, which is located approximately in the middle of the candle. Thanks to him, twisting is carried out. The insulator is usually broken off - the upper part of the candle. Key throws on the remaining part of the nest parts. After this should be smooth movements slowly begin to twist the part. In this case, it is necessary to keep the collar, head and extension cord strictly parallel to the axis of the device. The spark plug has a right-hand thread, so it must be twisted counterclockwise. The movements should be without applying large efforts in order not to break the thread, otherwise you will have to go to the service center, since you yourself will not be able to unscrew the broken part.

When you turn the key, you should listen to the sounds. If a rattle is heard, the part is twisted as it should be. If you felt a jerk and twisting began to pass easier, it may mean that the thread is broken. In this case, I recommend turning the key back, and wait a bit until the thread cools down. Then smooth movements in different directions to unscrew the broken part.

(Sz) are consumables, the purpose of which is to transmit a spark to the cylinders of the engine to ignite combustible mixture . Failure of the NW will lead to the fact that the normal operation of the motor will be impossible. In this article we will discuss how to use the screw for repair and how to unscrew the NW.

Possible difficulties in twisting

Before you unscrew and remove the spark plugs, you need to understand some of the difficult points that can happen when unscrewing.

Sometimes car owners who decide to unscrew and remove the candles, face dismantling problems that may be due to various reasons, in particular:

- Spark plug twisted. If the car owner used the key for spark plugs, the size of the design of which does not allow for optimal fixation of the NW, then this could well have happened.

- Often the cause is a thread, namely - its pollution. To avoid such a problem, the candle must be cleaned or purged before installing it in the thread.

- Not so often, but still there are situations when the candle is delayed with more effort than necessary.

Unscrewing instructions

Torque wrench - for dismantling NW

So, if you decide to unscrew the candle or make the restoration of the threaded element, then the instructions for dismantling the NW will help you.

How to unscrew the candle to prevent mistakes, and what to do with the unscrewed CW:

- Dismantling a device with a broken thread begins with removing the high-voltage cable and disconnecting the contacts. No need to rush, you need to be most attentive. After removal, the installation site of the SZ is cleaned with a compressor, this will remove all debris and residues from the device. Therefore, the thread cleaning procedure may take some time.

- After that, you will need to take a special torque wrench, it can be used to adjust the applied force. If the candle is not working and broken, then another tool cannot be used, since only this key will be able to enter the SZ well. In practice, device failure usually occurs on the upper side of the igniter component, which is a ribbed insulator.

- Using the key, without haste, it is necessary to unscrew the failed NW. The head and key of the key together with the extension must be installed exactly along the axis of the device. Unscrew the device smoothly, without making much effort. If you do not follow these recommendations, it can lead to a breakdown of the thread, which is fraught with new problems.

- During the dismantling of the NW, you need to listen to the sounds, because they can say a lot. If, for example, you hear a rattle when unscrewing it, then this indicates that everything is normal with the NW and it is gradually removed. If, after turning NW, the resistance did not decrease, most likely, the metal part of the structure has already begun to melt. In this case, the rotation can lead to the fact that the thread will be broken.

- After that, a solvent must be poured into the SZ nest - this substance will allow the thread to be flushed out and will facilitate easier unscrewing. Wait a few minutes after filling the substance, then smoothly and without sudden movements you can try to unscrew the NW to the end.

Candles can be twisted without a torque wrench, and it’s better to tighten them!

Carving on the NW and its restoration using futorki

The collar is a special connector in which the internal thread enters the external one with large size . Such connectors can be different in type, design and material - bronze, metal, copper and others. In this case, the greatest role is played by the strength of the metal (the author of the video is the channel Everything about ICE, tuning, advice and maintenance!).

The procedure for restoring the thread on the NW is a rather complicated task that must be carried out on the dismantled cylinder head. Cylinder head in advance should be installed on a milling or boring machine, without this in any way, after this hole SZ must be drilled to remove the broken thread. Further, cutting of a new carving for installation of a candle is carried out.

There are several ways to accomplish this task:

- The first option is quite reliable, but it will cost more. Special plates with a flange must be made on a lathe, usually bronze is used for this. A thread is cut inside the structure, one point should be taken into account - if the size of the internal thread is M14, then the size of the external one should be M18. It should be noted that in general, the production technology of such bronze devices will not ensure maximum structural strength with a smaller outer diameter.

- There is another option, but it is not as reliable as the first. First, because when cutting the thread and drilling the bore without dismantling the cylinder head with power unit , the alignment of the old and the new holes will not be ensured. Accordingly, in the end, you can just get a hole that is not suitable for repair. Secondly, without removing the head of the block, you can hardly avoid the ingress of waste products, in particular, chips, into the cylinders and most securely fasten the insert itself.